The Client:

ZBT (Zentrum für Brennstoffzellen-Technik GmbH). The outdoor carbon dioxide capture unit has been installed at ZBT’s Hydrogen Test Field in Duisburg, Germany.

Contract signing date: June 8, 2021

Delivery date: March 8, 2022

Users:

Research institutes, renewable energy enthusiasts and carbon reduction advocates.

Background:

In collaboration with ZBT’s Hydrogen Test Field, Soletair Power has deployed an advanced Outdoor Direct Air Capture (DAC) Unit as part of ZBT’s PtG-MSE project. This groundbreaking initiative aims to create a closed carbon cycle using regenerative energy, with DAC technology playing a pivotal role in supplying CO2 for the operation of a methanation plant. The modular outdoor DAC unit is a testament to cutting-edge carbon capture solutions and sustainable energy research.

Pain Points:

ZBT wanted to solve the following challenges:

- Net Negative Emissions: Addressing the urgent need for net negative emissions and reduced atmospheric CO2 levels.

- Innovative Carbon Utilization: Seeking efficient ways to capture and utilize atmospheric CO2 for sustainable energy generation.

- Research and Development: Exploring direct air capture technology’s feasibility and effectiveness for real-world applications.

- Onsite CO2 Capture Solution Deployment: ZBT needed a carbon dioxide-capturing solution of their own.

Solution:

Soletair Power’s Outdoor DAC Unit is designed to capture up to 21 kg of CO2 daily from ambient air, compressing it to over 10 bar with >98% purity. Housed within a 12 m × 2.4 m × 2.87 m container, the unit utilizes weak base anion resin as an adsorbent for CO2 capture. This collaboration with ZBT addresses the essential need for CO2 supply in the methanation process and fosters research in carbon utilization technologies.

Technical Specifications of the Unit:

- Use: Commercial project for high-volume CO2 capture

- Carbon capture capability: YES

- Carbon storage capability: YES

- Carbon capture capacity: 21 kg/day (with each container)

- Dimensions: 12 m × 2.4 m × 2.87 m (l x b x h)

- Regeneration temperature: Below 100°C

- Purity of desorbed CO2: 98%

- Compression: >10 bar at >98% purity

- Adsorbent: Weak base anion resin

- Noise level: 62 dB

- Delivery period: 12 months

- Installation time: 1 day

- Control area: Siemens SIMATIC HMI Panels

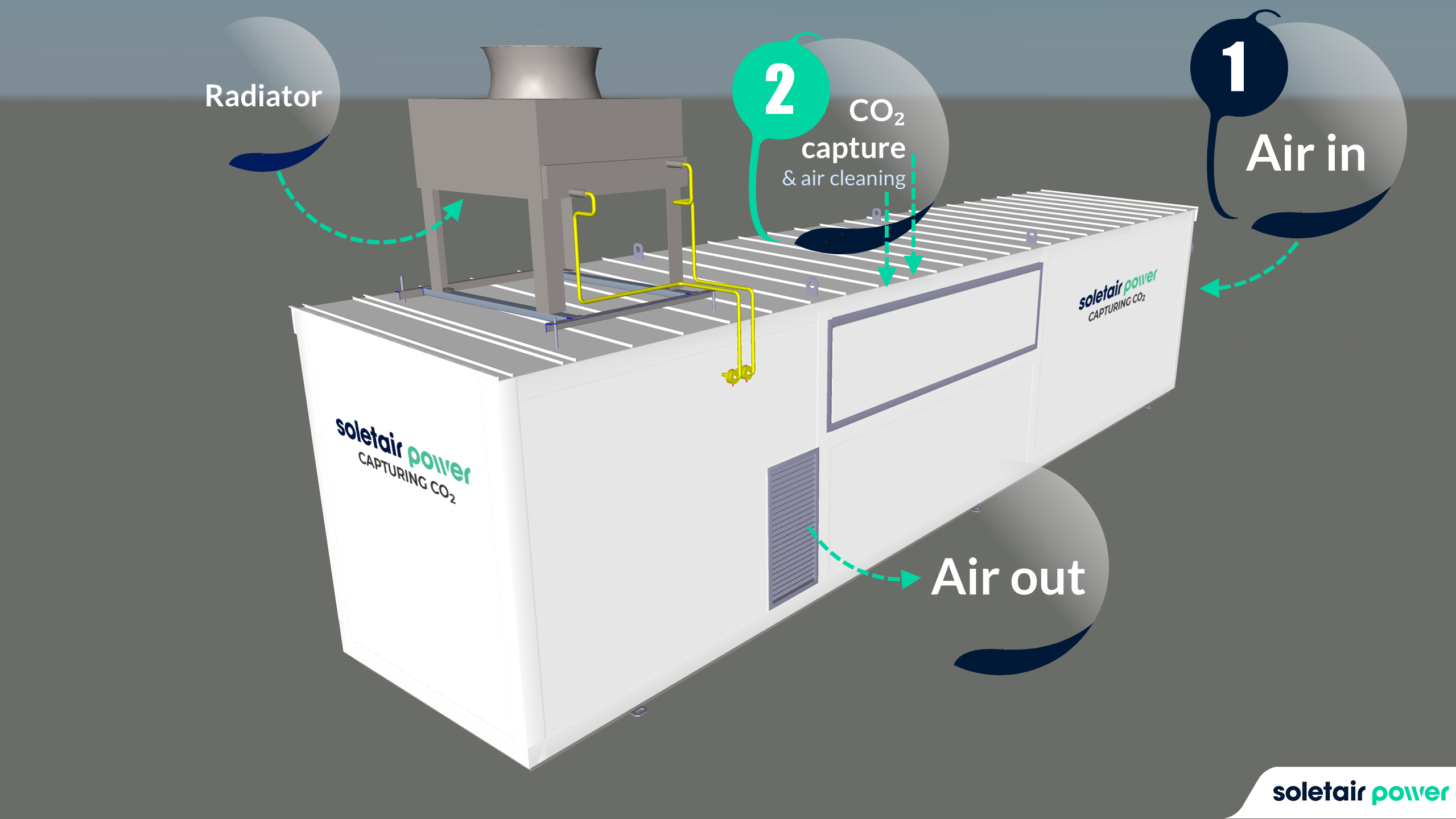

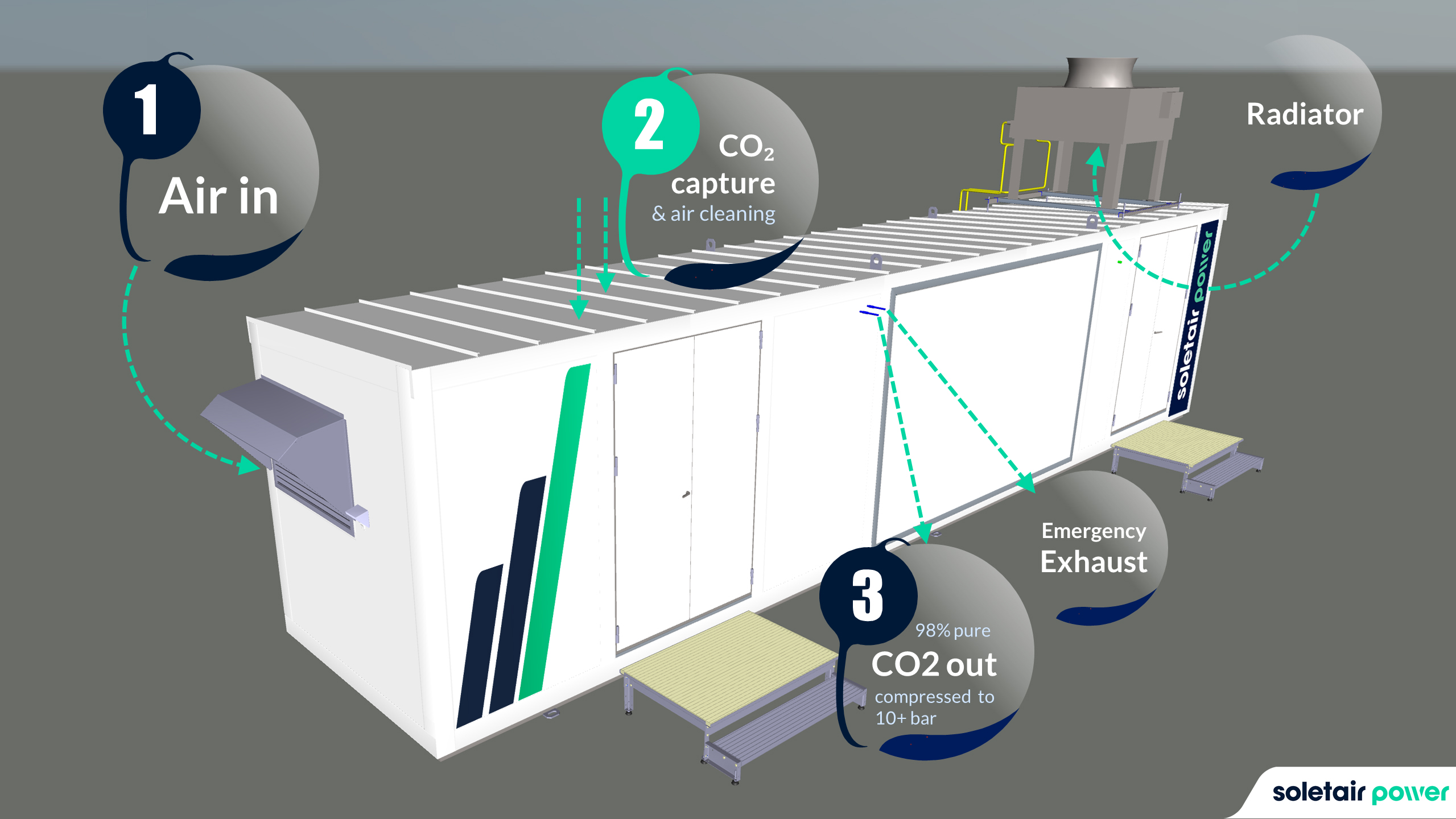

Working Process:

This unit uses weak base anion resin as the adsorbent for CO2 Capture. The lifespan of this resin has been tested using a rapid multi-cycle-per-day test rig to ensure its capture performance and service life.

A large volume of air needs to be moved inside to capture the required amount of CO2. Using Computational Fluid Dynamics (CFD), a vessel has been designed that can hold the optimum amount of sorbent and maintain the required airflow rates while limiting the pressure drop to allow the use of conventional fans. To ensure uniform distribution of air inside the vessel, the geometry inside is made highly symmetric allowing uniform velocity even at large airflows.

To produce high-purity CO2, the temperature-vacuum adsorption process is used. In the vacuum-swing step, the air inside the chamber is removed using vacuum pumps to achieve a vacuum level of below 100 mbar. In the temperature-swing step, the sorbents are heated below 90°C promoting the release of CO2 and water. Heating is accomplished using warm water flowing through specially designed heat transfer elements inside the vessel.

Due to the low-temperature level of operation of the system, several sources of heating can be used. In this project, purely electric heating of water in a hot water silo is used. In other projects, there were heat pumps, and in some cases, district heating plus boosters can also be used.

The gas collected from the vessel is a mixture of CO2 and water which is separated using various physical methods that lead to the condensation of water, leaving out dry CO2 as the product. This CO2 is collected using dry-vacuum pumps to eliminate oil contamination ensuring ease in downstream use of CO2. The product gas is stored in buffer tanks operating at up to 10 bar, from where gas boosters are employed to compress CO2 up to the pressure required by the customer.

Modularity:

Soletair Power Direct Air Capture units follow a modular design principle allowing customers to install multiple units and assemble them on site. Customers may choose to get a unit with a large production capacity, or they can also get a regular unit and get add-on units later to increase the capacities of production.

Quality Assurance:

Starting from the development of sorbent to the design of the vessel – all decisions are guided by extensive research and data gathered from experiments. The sorbent for this case has been chosen after being subjected to long-duration cycles and underwent a battery of tests. Active collaboration with local universities and research institutes ensured a proper understanding of the properties and limitations of the sorbent. Extensive use of computational fluid dynamics modeling further substantiates the performance of the sorbent. Soletair Power employed design-of-experiment principles to ensure the vessels had the lowest pressure drop given the technical boundaries of the project. The parts such as the pumps, sensors, and process valves used in the deliveries are top brands and are obtained from reliable suppliers. The components undergo several technical checkpoints before being put into use.

Safety Assurance:

This outdoor Direct Air Capture system comes fully instrumented to ensure stable and safe operation. The customer can gather operational data from relevant process instruments. The container is also equipped with indoor air and product gas quality monitors, control units, and several smoke detectors. The unit can be integrated into the customer’s system by using industrially relevant communication protocols.

Key Benefits:

The Outdoor Direct Air Capture Unit offers a range of advantages:

- Sustainable Carbon Cycle: Facilitating a closed carbon cycle by supplying captured CO2 for the methanation process using renewable energy sources.

- Cutting-Edge Technology: Demonstrating the feasibility and effectiveness of outdoor direct air capture technology for CO2 capture.

- Research Advancement: Contributing to valuable insights in the field of direct air capture and carbon utilization through collaboration with ZBT.

- Carbon Reduction: Directly addressing the need for net negative emissions and supporting efforts to combat climate change.

The deployment of Soletair Power’s Outdoor DAC Unit at ZBT’s Hydrogen Test Field showcases a remarkable step toward achieving sustainable carbon utilization, research advancements, and net negative emissions.

For more information about this HVAC Integrated Direct Air Capture Unit, please visit https://www.zbt.de/nc/aktuell/news-anzeige/detail/News/co2-capture-neue-direct-air-capture-anlage-auf-dem-wasserstoff-testfeld/