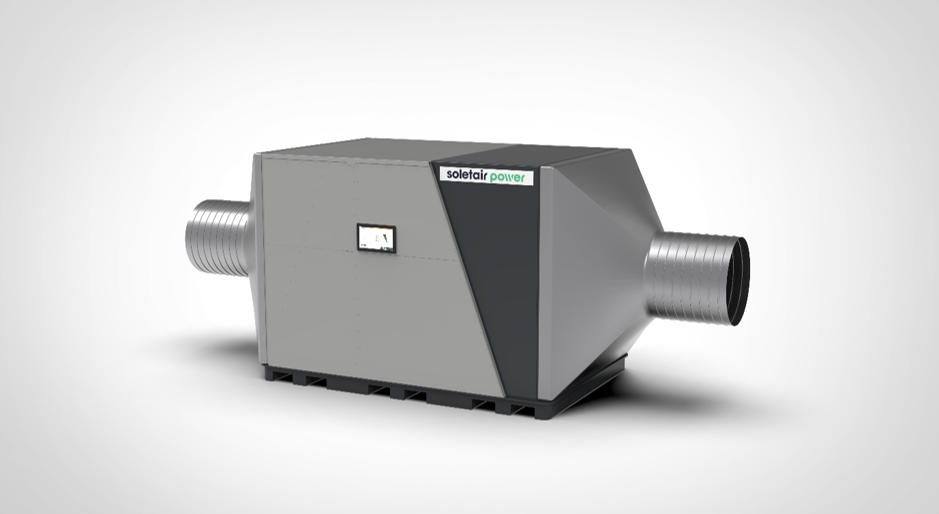

Technical Specifications of the Building HVAC/Ventilation Integrated Direct Air Capture of CO2 Unit from Soletair Power

We remove CO2 from the air by integrating a technology called “direct air capture” in buildings. Then the HVAC system starts to capture CO2 directly from the air, reducing the atmospheric concentration of CO2 by using renewable energy.

From the HVAC system, incoming air is pushed through our filters containing sorbents, and carbon dioxide is adsorbed by them. When the filter is saturated, the machine is closed and regenerated via vacuum & heating to collect the CO2. The captured CO2 is stored in a separate storage container.

Amine functionalized sorbent is used by Soletair Power within its carbon capture systems utilizing a temperature vacuum swing adsorption process.

Minimizing the energy required for carbon capture has been the primary goal behind much of our carbon capture research.

Our Approach

Direct air capture of carbon dioxide is often associated with large filter machines piled one on top of another and moving large volumes of air. Large contact points are required due to the small concentration of carbon dioxide in the air and because of the large daily production targets of these plants. As air is pushed into the filter, carbon dioxide and moisture are trapped or adsorbed. When the filter is saturated with these compounds the machine is closed and regenerated via vacuum and heating to collect the CO2 and water. Moisture is condensed leaving pure CO2 for compression.

Soletair Power delivers solutions for capturing CO2 in air supplied to building ventilation. The adsorption and regeneration principle is used in our system to capture carbon dioxide but the dimension is compact. The captured CO2 is stored in a separate storage container.

Soletair Power’s ventilation-integrated CO2 capture system is designed to work within established design requirements. The system is aimed to meet the ventilation speed typically in m3 sec-1 and the customers preferred indoor CO2 level measured as parts per million or ppm.

For a standard ventilation unit handling 3.3 m3 sec-1, our CO2 capture system has a dimension of 3 m (L), 3 m (W), and 3 m (H) and can produce around 50 kilograms of carbon dioxide per day. Due to the space limitation in the HVAC room, the system’s piping, and dimension can also be modified to fit the customer’s specifications.

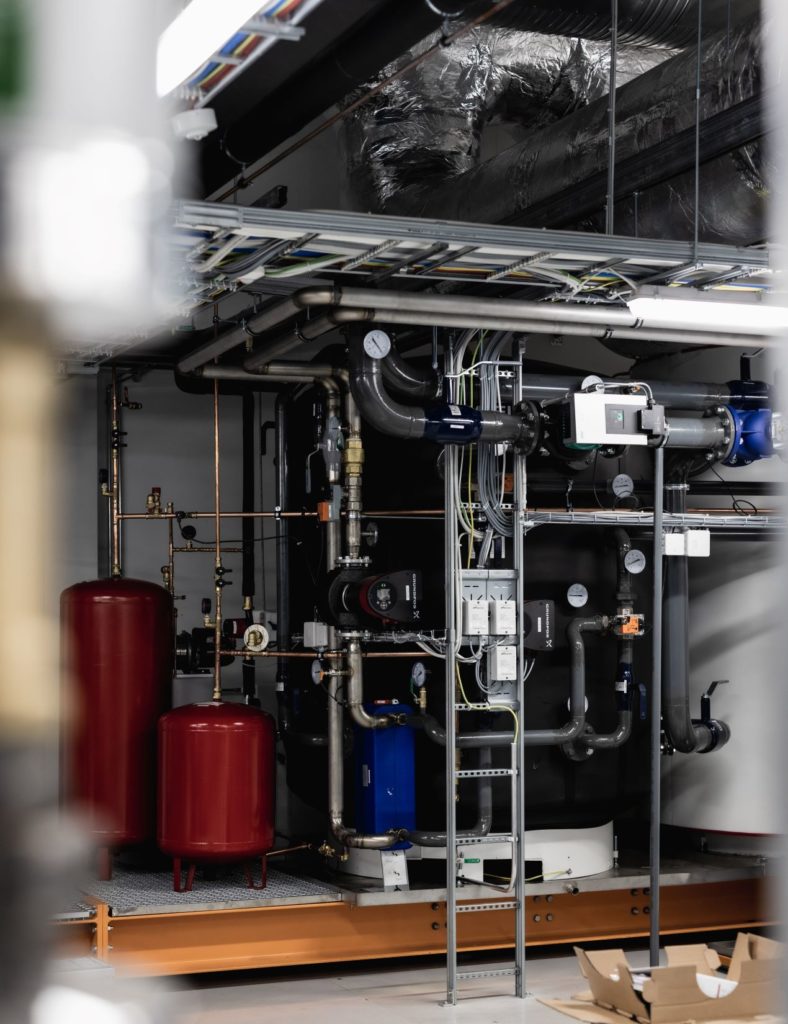

Visual outlook of our system installed in an HVAC room

Below is an example of the visual outlook of our system installed in an HVAC room. The system can be installed as a turn-key solution or can be assembled on-site. The latter is especially suited to building retrofit installation where the access path to an HVAC system can be limited.

The system has a modular design principle therefore it is easy to install multiple units if required. The storage of CO2 is done in a separate room inside or near the building. Captured carbon dioxide from Soletair Power’s system is piped to that room.

For more information:

Petri Laakso

CEO, Partner | Tel. +358 40 544 5646 | petri.laakso@soletairpower.fi